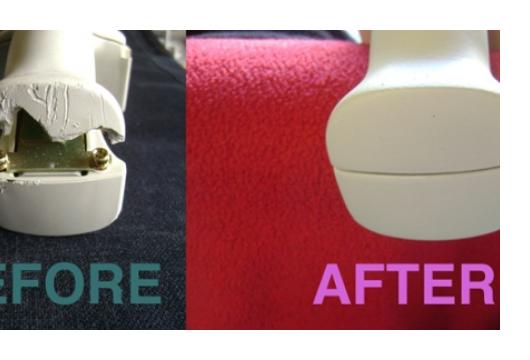

A very challenging restoration on a fluoro handle from a Toshiba CT Scanner for an insurance company. The cost for replacing this part would have been over $12,000. We did the job for 1/10 of the OEM cost.

A GE Diamond Mammography unit badly damaged in shipping. Left view show the back metal cover crushed

Over the years, having a full medical equipment paint and body shop in-house we’ve gotten pretty good at doing cosmetic “face-lifts” on the equipment we sell. As a matter of fact, 90% of the equipment that leaves our refurbishing facility– whether headed to Azerbaijan or the Mayo Clinic– gets either a partial, or total “head-to-toe” cosmetic refurbishing. This usually includes sanding down to the original surface, fiber-glass fill and repairs, bondo for smoothing pitted and dented metal panels, primer, and finally a fully matched factory repaint, along with new decals. Yes, we do this all here in-house.

GE Diamond mammography back cover fully restored, and reinstalled. System was pre-staged, tested.

As our guys took on greater challenges, our “Restoration Team” was born. These days we do many restoration jobs for insurance companies, shipping companies, other medical equipment dealers, hospitals, and even the OEMS’s. Our restorations are THAT good. Take a look here for some recent examples. Also, watch this space as our “Restoration Team” will soon get their own blog.

GE Diamond mammography cover fully repaired and repainted, waiting to be reinstalled on the system.

Removing broken covers on a digital mammography system or a CT Scanner is often careful work, and may require us to replace damaged clips and/or brackets that serve as closures to fit the covers back together. Much of this type of work involves fitting dissimilar materials, such as plastic and metal, or fiberglass and metal, and occasionally requires us to have custom pieces molded or tooled off-site. We are well prepared to do this work, in addition to welding of nearly all metals– aluminum, stainless steel, brass, and others.

On some restoration jobs we are further asked to “Pre-Stage” the equipment prior to return to the client, i.e. to do final or preliminary testing after the cosmetic restoration has been completed to verify functionality. Our large equipment staging areas are equipped with single-phase and 3-phase power, from 110v to 480v, to accommodate all types of medical equipment testing.

Future plans are to provide repairs and restorations of medical imaging equipment or systems damaged by water, fire or smoke. In this case we are developing the capability to clean, repair, and decontaminate a wide variety of equipment without disturbing internal circuitry, in order to enter the field of true electronics recovery. Stay tuned.